OUR PRODUCTS

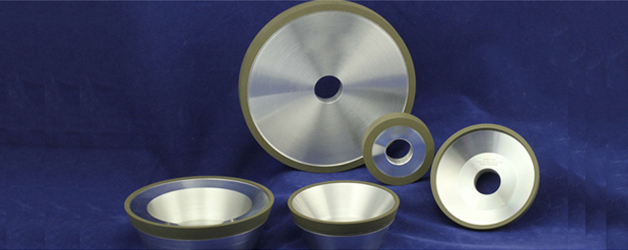

DIAMOND/ CBN RESIN BOND WHEELS

These wheels are widely used to grinding difficult-to-machine materials such as tungsten carbide, ceramics, glass, silicon as well as ferrous materials such as HSS steel, hardened steel, alloy steel and other sintered ferrous metals.

Resin bonds wheels can be designed for both wet and dry grinding, showing good free cutting qualities.

Characteristics of resin bonds grinding wheels

- Various properties when added with organic or inorganic fillers.

- High grinding efficiency, free cutting, good surface finish;

- Resin bonds wheels have shorter life compare with metal bonds wheels, but have much better cutting abilities when processing hard-to-grind materials such as cement, ceramics, etc.

Resin bonds Diamond grinding wheel is particularly suitable for machining of hard, brittle and short-chipping materials such as tungsten carbide, cermets, ceramics, glass, quartz, ferrites,

semiconductor materials, graphite, glass fiber reinforced plastics, etc.

Resin bonds CBN grinding wheel is suitable for machining of ferrous materials such as high speed steel, chrome steel, hardened steel, nickel based special alloys, etc.